On Wednesday the 16th and Thursday the 17th of November 2022, the Hanze Makerspace visited one of the leading 3D printing industry events of the year, called Formnext. Together with our friends over at Binder3D, Kjell Neumann, Johan Hekman, Harm Grijpstra and myself, Kris Galama, visited the two day event. So you might wonder, what is Formnext?

Formnext is the leading industry platform for Additive Manufacturing and industrial 3D Printing, and offers an international meeting point for anyone who wants to be a part of the next generation of intelligent industrial production.

The event was hosted in the facilities of the “Messe Frankfurt”, which as you would’ve guessed was in Frankfurt, Germany.

So what did you see?

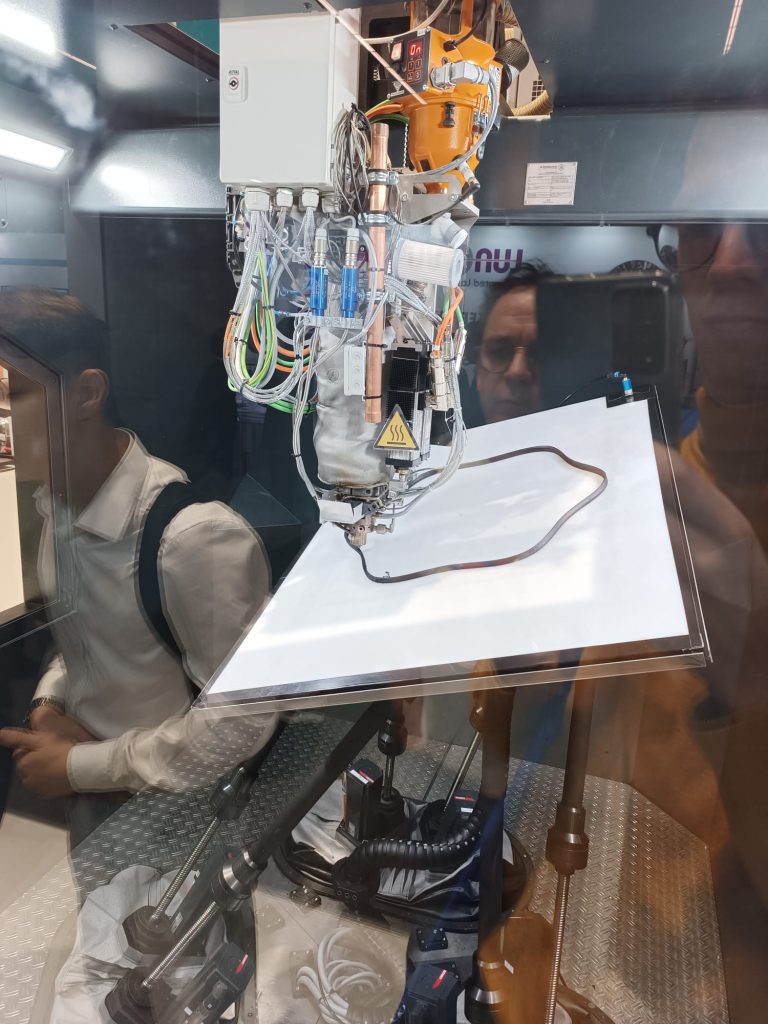

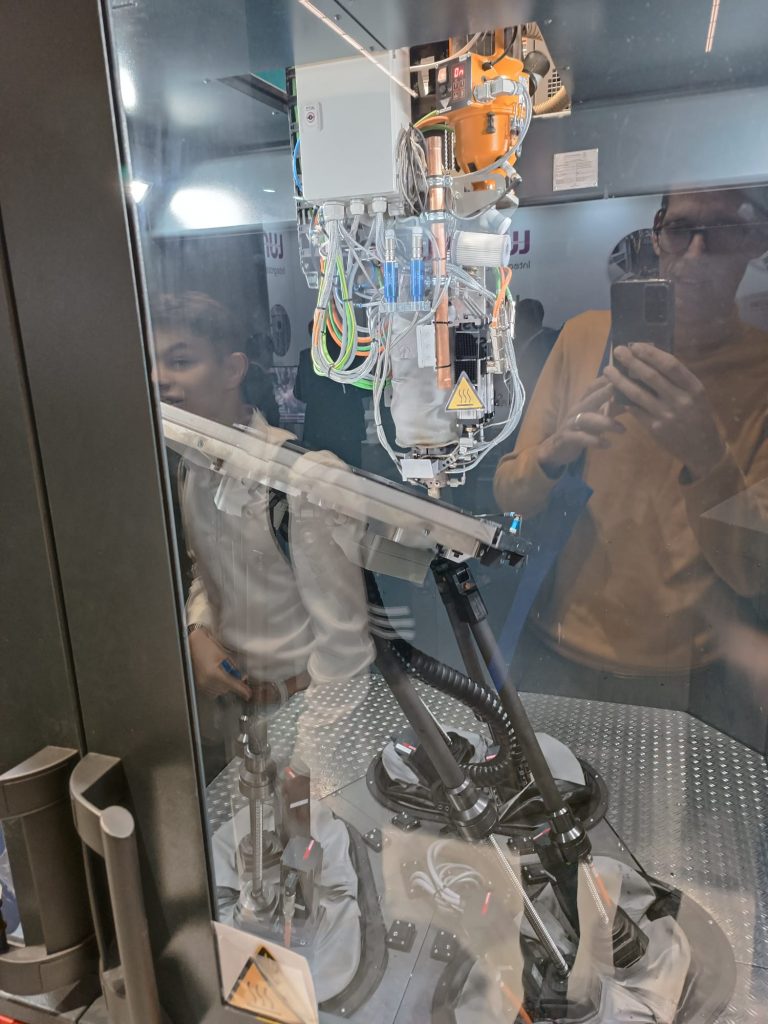

Companies from all over the world were there to show off their new up and coming manufacturing technologies, ranging from the desktop-sized FDM printers by Prusa3D that we use in the Hanze Makerspace, to the absurdly large WAAM (Wire Arc Additive Manufacturing) printers that require us to construct another building if we would like to integrate that into the HMS.

Another cool technology that we saw that used WAAM printing, was that you can first print your part, and then mill it down to what you need. In the picture below, an existing metal part has new material printed on top of it, and then it gets milled down to what the part is supposed to end up as.

Anything other than metals?

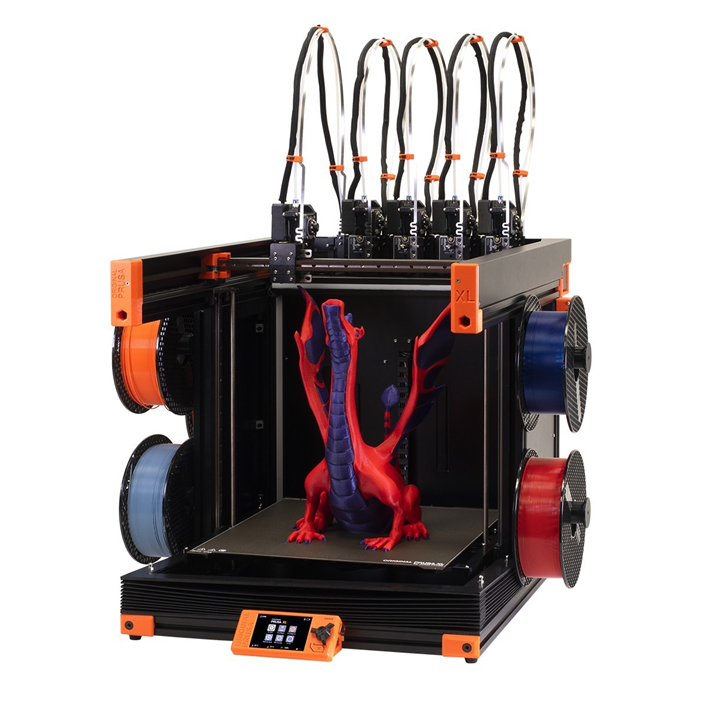

While metal printing seems to turn into the hot new thing in the 3D Printing business, we also have our standard FDM printers, like the Prusa’s that we have, that were getting up to cool stuff during our visit in Germany.

One of the new printers from Prusa, the Prusa XL, can feature up to 5 tool heads, which means that you can support up to 5 different colours or even materials in the same print

But that wasn’t all, Prusa also debuted their new Autonomous Farm System, or AFS for short, featuring 9 printers at the Formnext expo. Check out the video below!

Where the HMS now needs assistants to pull your prints off the plate, this system takes off the beds automatically, and prepares the printer for it’s next job in the queue. Truly a wonderful system of automation and machine magic!

5D Printers

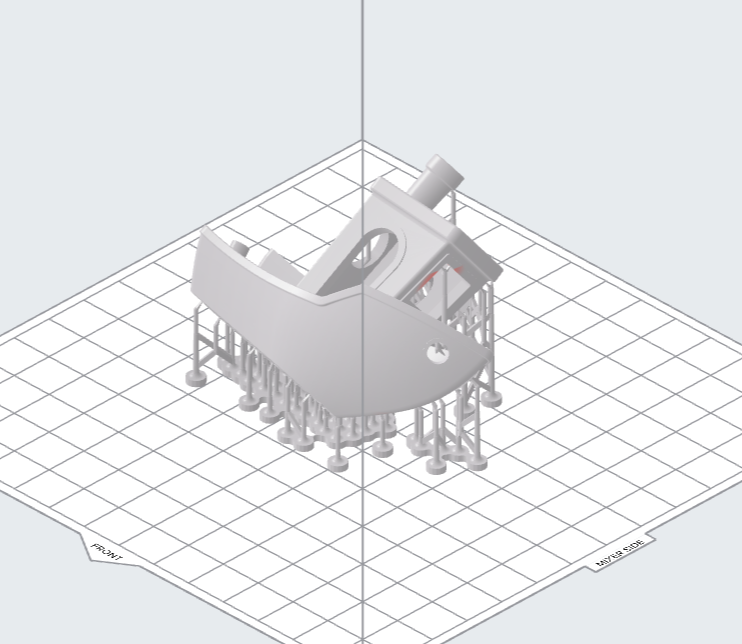

You’ve heard of 3D printers before, but did you know there’s also printers that can print in 5 dimensions?! Okay, it’s not 5 dimensional, but “5 degrees of freedom”, or 5-DoF. Where your standard 3D printer works on the X, Y and Z axes, a 5D printer works with aforementioned three axes, but also allows for rotation of the X and Y axes, creating 5 degrees of working space.

One of the defining features of printing with 5-DoF printers is that you need way less supportive material to keep your prints from falling over, or that the prints are structurally more sound when printing with alternative so-called toolpaths, the path the extruder follows to create the 3d print.

Concrete!

Okay, not just concrete, but also porcelain!

Printers like these can be used to construct entire statues, but the concrete printers with bigger nozzles could even be used to build a whole house. No more manual brick-laying or concrete pouring, when you can instruct a 3d printer to do it for you!

Something FDM, but a little different

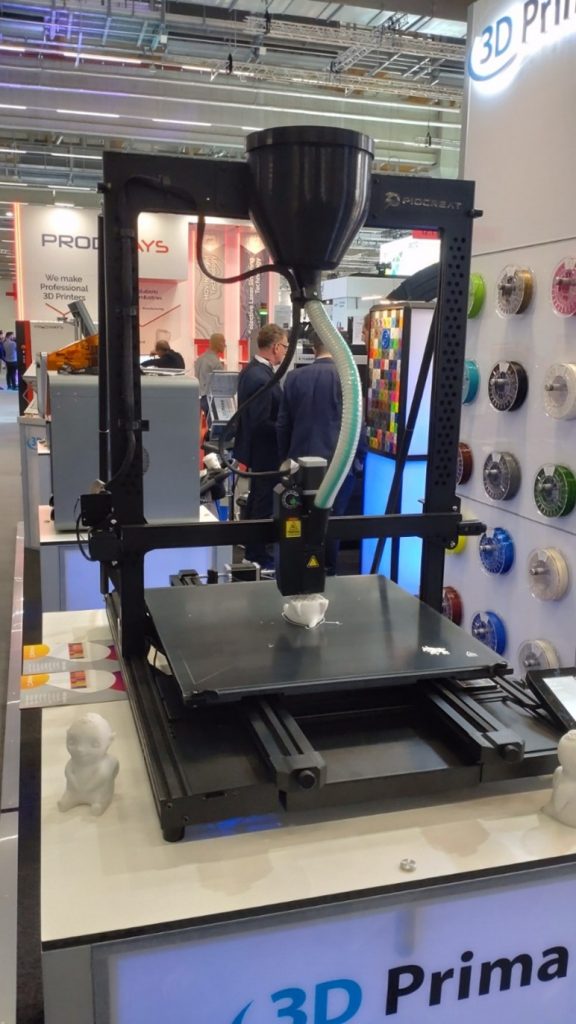

A really interesting technology that we have yet to integrate into the HMS is the use of Pallet Extruders.

These Pallet Extruders, rather than your conventional spool of filament, use raw pallets of plastic to create your 3D print.

The upside of this is that you can even recycle failed prints and use that as “fuel” for the printers, as long as the chunks are small enough to get fed into the printer.

Our coordinator Kjell is actually building one himself, so stay tuned for any updates there!

Other honourable mentions

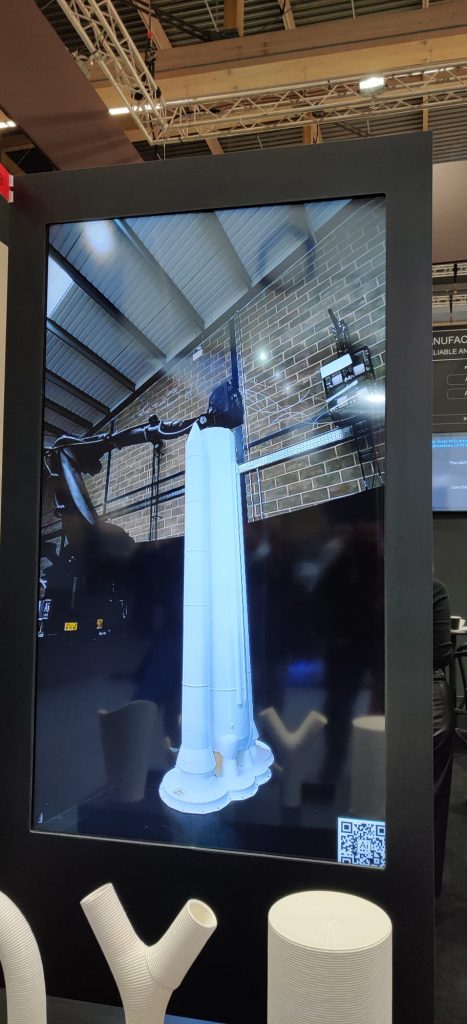

Next to the interesting and cool industry stuff, we also saw some funny things such as a 3 meter tall NASA Artemis rocket, a fully 3D printed StarGate from the similarly named TV show, and a duck!

Last but not least

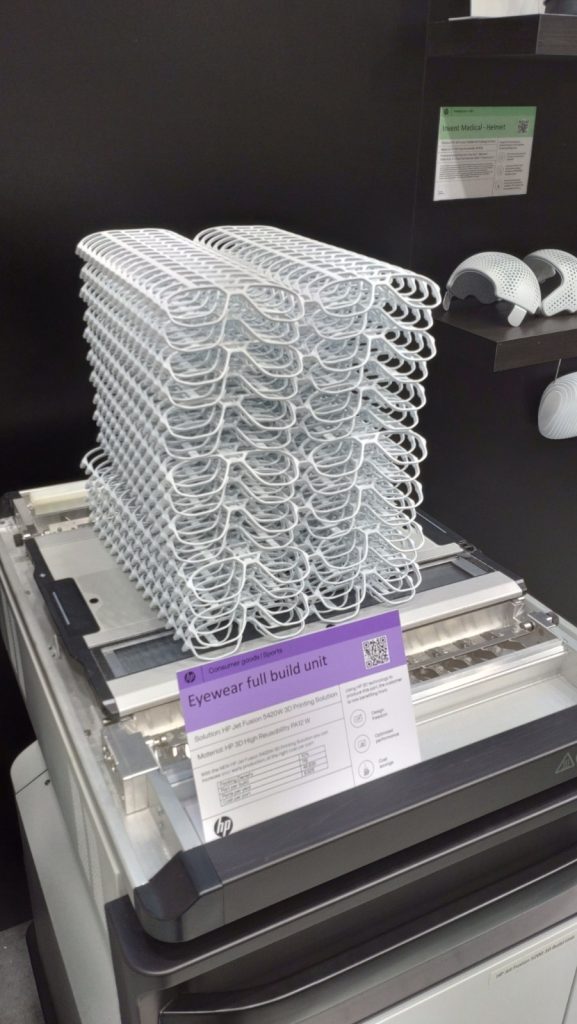

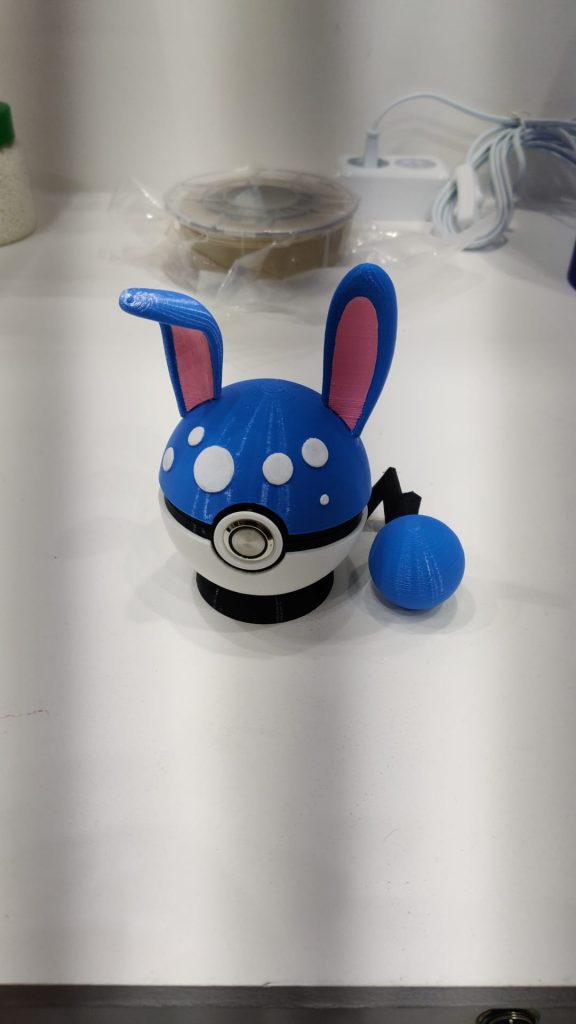

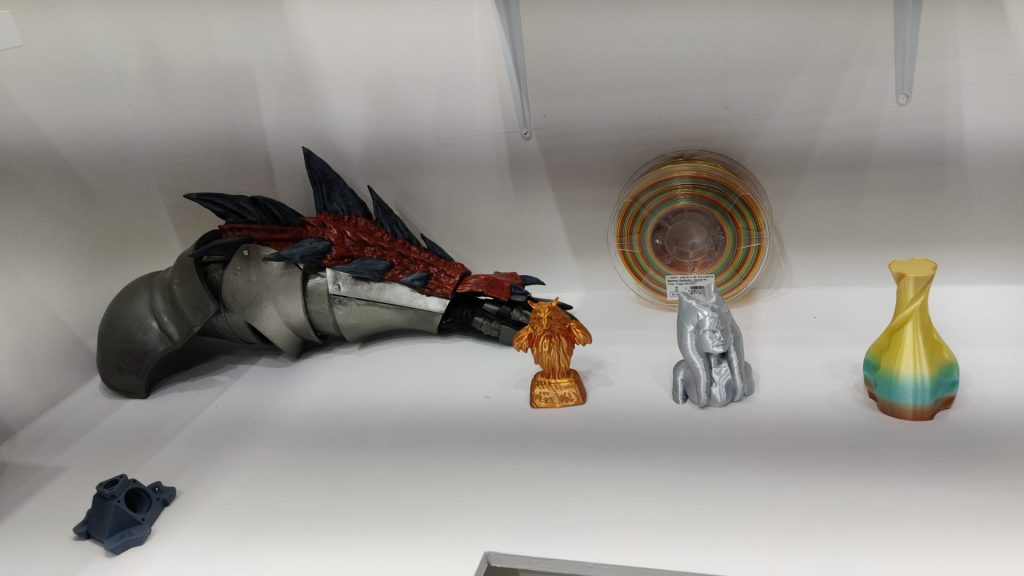

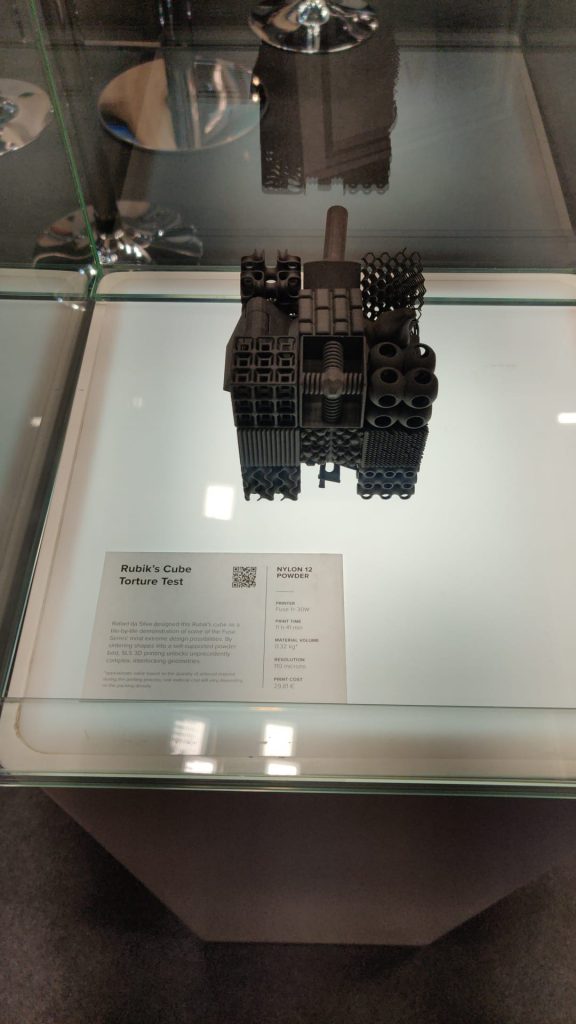

The rest of the pictures that we took during Formnext.

Our take-away from this experience?

The main take-away on what we’ve learned while at Formnext is that the industry of 3D Printing comes in many different forms, from standard PLA plastic to silver metal printing, from concrete to nylon fibre. Kjell is already building his own Pallet Extruder printer as we speak, and I’m sure that the industry will keep surprising us in the future.

Signing off,

Kris Galama, Practical Instructor of Digital Technologies